The Ultimate CNC Circular Table

The SANDEX Feeder is a vibratory parts feeder that uses an ellipsoidal motion created and controlled by a cam. The performance and stability delivered by this extremely precise motion offers the production floor the following benefits, all of which raise the efficiency and added value of automated production.

Feed rate adjustment is a simple matter of changing the motor speed. No fine tuning required.

The frequency of the vibration controls the feed rate, which depends only on the speed of the internal cam. Adjusting the speed of the motor changes the amount of rotation of the cam, without necessitating vibratory adjustments to avoid resonance or other effects. The unit can be designed for feeding and conveying at high speeds, with good efficiency at various feed rates.

Smooth conveying system prevents damage to parts.

The precise ellipsoidal motion produces a stable feeding motion that conveys objects smoothly, with minimal damage. It also improves the success rate for complex sorting tasks.

Cam driven for powerful conveyance, even for heavy objects.

Two cams and their cam followers are used to produce a vibratory conveyance motion powerful enough to consistently convey any number of workpieces. The amplitude is consistent regardless of speed or work volume, which eliminates the need for constant adjustments.

By remaining consistent over time and various feeding or conveying conditions, the rate of operation of the automated machine increases.

Cams also operate with less noise, which can significantly improve the work environment. (Watch the video on the right for an example of feeding bolts.)

By remaining consistent over time and various feeding or conveying conditions, the rate of operation of the automated machine increases.

Cams also operate with less noise, which can significantly improve the work environment. (Watch the video on the right for an example of feeding bolts.)

Particularly effective with powders and other materials that are difficult to feed.

The precise vibratory motion and smooth feeding action is particularly suitable for delicate workpieces. Starts and stops are inherently good, making these feeders ideal for conveying fixed amounts of powders. (Watch the video on the right for an example of feeding fixed volumes of powder.)

Continues to feed to the last object, reducing the work associated with changeovers.

The cam produces a powerful yet stable vibration that ensures the entire lot is fed down to the last workpiece.

This eliminates the need to eject stray objects during changeovers, and allows the SANDEX Feeder to be used in normal operation mode throughout the production cycle.

This eliminates the need to eject stray objects during changeovers, and allows the SANDEX Feeder to be used in normal operation mode throughout the production cycle.

No parts to wear, easy to maintain.

The vibration of the SANDEX Feeder is produced using a cam mechanism. Cam followers transfer power by wearless rolling contact, making the unit essentially maintenance-free. The motion is rigidly defined so there is less need for adjustments and maintenance. The unit provides long-term, stable feeding.

Technical Description

■ Ellipsoidal Vibration

All SANDEX Feeders use an ellipsoidal vibration pattern for its high conveying efficiency. The smooth, jerk-free properties of ellipsoidal vibration is suitable for a wide range of conveyance and sorting applications that deal with difficult to handle objects. The conveying speed is linear to the frequency, making it easy to adjust the speed to line requirements.

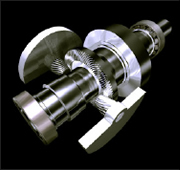

■ Mechanism

The vibration of the SANDEX Feeder is created using a pair of cams, one for the horizontal component, the other for the vertical component. This ensures the amplitude of the vibration is consistent, regardless of the frequency. Once adjusted, the frequency of the SANDEX Feeder can be varied infinitely without ever causing the amplitude to change. This prevents interference from occurring with other equipment at the point of transfer.

■ Cams and Cam Profiles

The biggest benefit of a cam mechanism is the flexibility it offers with creating motions (vibration). This, together with stability, durability, accuracy, and rigidity at high speeds, are the essential and important qualities that make for a good vibratory conveying mechanism. Sankyo's cam and cam profiles are the result of many years of research and development. These time-proven solutions achieve the ideal motion for high-speed, high-efficiency conveying and feeding.

■ DSU (Dynamic Stabilizer Unit)

The DSU reduces the propagation of undesirable vibration to other devices and the chassis to which the feeder is mounted. It uses inertia created internally to offset vibration generated by the feeder. This ensures smooth and stable operation of the SANDEX Feeder. The vibration remains consistent and stable for reliable conveying and feeding. The DSU works regardless of the vibration frequency.

■ Environmental Initiatives and Recycling Issues

Under the theme ECO.CAM, Sankyo continues to pour the results of R&D efforts into its products by constantly searching for better mechanisms and cam curves. The cam mechanism used to create the ellipsoidal vibration in the SANDEX Feeder not only produces a superior conveying motion, it also works so efficiently that it uses less energy. And, more than 90% of its parts are recyclable.

Typical Configuration

Tooling Development

Sankyo develops tooling for the SANDEX Feeder based on the workpiece to be handled and the customer's requirements.

At least two workpieces must be provided to analyze and develop the tooling.

Fill out the information on the next page to have Sankyo study your application. Note, Sankyo does not offer tooling development as a stand-alone service.

At least two workpieces must be provided to analyze and develop the tooling.

Fill out the information on the next page to have Sankyo study your application. Note, Sankyo does not offer tooling development as a stand-alone service.