Heat treatment

Focuses on high accuracy, high rigidity, and long anticipated life

Our products are manufactured, from development and design, choice of materials and heat treatment, to processing, assembly and inspection, in our integrated production system. This is how we supply high-performance products that always satisfy our cus tomers,.

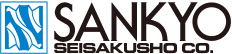

The heat treatment process is one of the most important processes for determining the ultimate strength, wear-resistance, and extended service life of our pro ducts.

We carry out surface treatments such as vacuum quenching, carburizing quenching, induction quenching, tempering and so on to suit the characteristics of the parts, in an optimally controlled heat treatment process, and conduct inspections for texture, depth, hardness, etc. The care and reliability with which we perform these is why we have become a JIS certifi ed factory.

Vacuum hardening

Oxidative scale is not formed during our high-temperature heat treatment. This process prevents contamination from entering the products.

This hardening process strengthens the interior of the material, so very strong parts can be produced.

Carburizing quenching

Carbon penetrates through the surface of a heated part and then the metal is quenched.

This surface treatment increases only the hardness of the metal near the surface.

A part treated this way has greater toughness and is highly res istant to shocks.

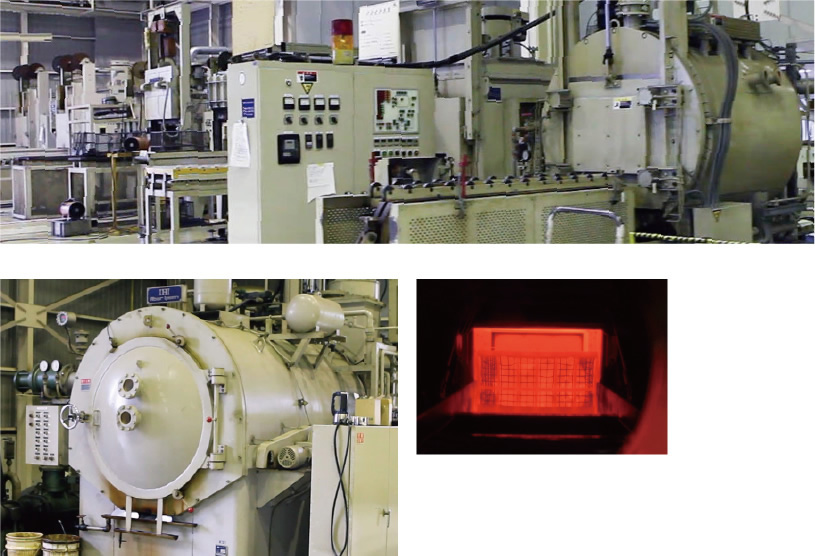

High frequency induction hardening

This surface processing method only increases the hardness of the metal near the surface of the part. The surface is heated and cooled using high frequency electromagnetic induction. This method takes a shorter time to raise the temperature and cool down, so it is especially useful for the partial quenching of large parts or complexly shaped parts.

| Focus on qualit | Quality assurance | Design technology | Production facilities | Thermal treatment | Personnel training and education |