Quality assurance

Measurement technology

The environment in the precision measurement room is strictly controlled to maintain a constant temperature. This prevents temperature variations from affecting the precision of the measuring instruments and the parts being processed.

Measuring free-form objects, such as cams, requires a high-precision measuring system with 3 orthogonal axes and 1 rotating axis. Our staff members measure cams. shapes using the most precise 3D measuring instrument available.

We can evaluate our measurements of cam shapes to the micron level using our proprietary 3D CAD modeling system to verify the 3D measurement results. The results of this evaluation are applied immediately to the machine tools dedicated to processing the cams. Feedback is used to correct the manufactured shape to micron level precision.

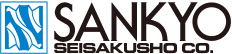

3D surface shape measuring

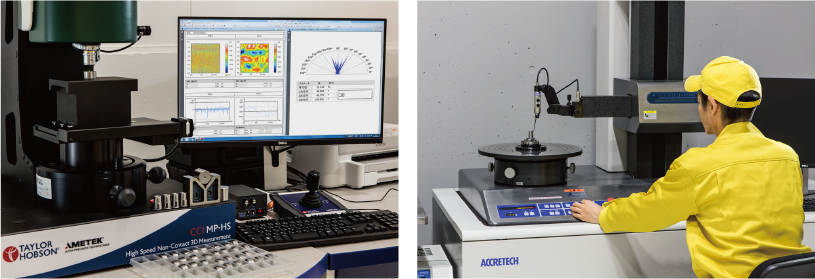

instrumenRoundness measurement

This measures dents and protrusions on sliding and rolling surfaces as nanoscale topographic features.

This makes these surfaces function superbly in their final applications.We measure geometric shape tolerances, such as roundness and cylindricity, to guarantee the design quality of our products.

Surface roughness and shape

measurementMeasuring angles precisely

We measure deviations from desired shapes, such as roughness and crowning, to guarantee we are achieving our design quality.

We measure the rotary positioning precision of items such as indexes and roller drives to guarantee our products. quality.

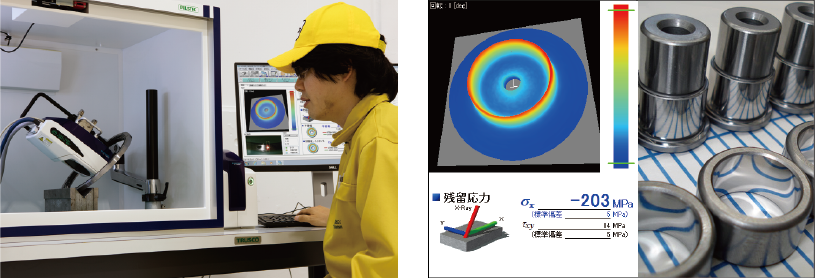

Measuring residual stresses

Measuring residual stresses and hall-widths enables us to evaluate the surface characteristics of materials.

| Focus on qualit | Quality assurance | Design technology | Production facilities | Thermal treatment | Personnel training and education |