Zero-backlash Technology

Delivers Unsurpassed "Motion".

In FA equipment, servo-driven motion control systems play a major role in defining the performance of the equipment. Machine specifications and performance requirements are developed assuming the given system can produce the expected motion. However, if the motion control system has backlash, lacks rigidity, or has other control instabilities, the output motion will deviate from the control input and make it difficult to achieve the expected performance.Delivers Unsurpassed "Motion".

The

Striving for True Quality Motions

With conventional motion equipment, the quality of motion was primarily assessed by its accuracy and rigidity in a static condition. In reality, accuracy and stability impacts the performance of FA equipment in motion just as much as it does in standstill conditions.

Backlash or poor responsiveness can degrade the dynamic accuracy of motion control equipment, preventing it from creating the motions intended by the control references.

The uses zero-backlash technology to create output motions that are faithful to the input control references, which delivers improved performance levels in all kinds of FA equipment.

uses zero-backlash technology to create output motions that are faithful to the input control references, which delivers improved performance levels in all kinds of FA equipment.

Backlash or poor responsiveness can degrade the dynamic accuracy of motion control equipment, preventing it from creating the motions intended by the control references.

The

Boosts Performance of Various FA Equipment

High-speed Positioning

Settling time is instantaneous for precise positioning. Speed variation during motion is minimal for accurate synchronized operation. Virtually maintenance free for reduced life cycle cost of the entire FA system.

High-accuracy θ Axis Positioner

The output shaft of the  has very minimal runout, which makes it suitable for precision θ-axis positioners and alignment tables. Its thin, compact design makes it ideal for X-Y stages and other positioning units as well.

has very minimal runout, which makes it suitable for precision θ-axis positioners and alignment tables. Its thin, compact design makes it ideal for X-Y stages and other positioning units as well.

Swing and Oscillating Arm Drive

Improved speed and reciprocating repeatability allows thin-profile drive layouts for compact integration. Piping and cables can easily be passed through the hollow bore in the large diameter output shaft.

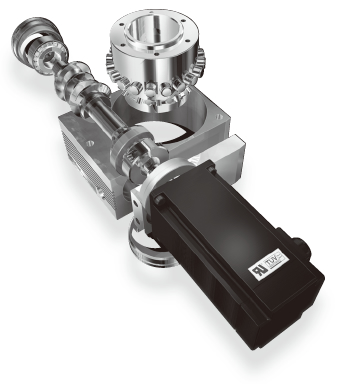

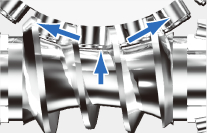

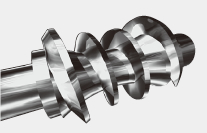

Preload

Wedge-shape ribs on input shaft maintain contact with the roller followers under preload to completely remove backlash. Preload is adjusted by turning the adjustment mechanism on the input shaft.

Input Shaft

The steel alloy input shaft is made to meet extremely tight tolerances using the latest in machining theory and equipment. These shafts are balanced to suppress self-excited vibration under high speed rotation.

Roller Followers

Roller bearing construction transfers torque by the rolling action of the roller followers. Rolling contact maintains the initial accuracy, even for extended periods of use.

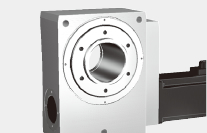

Oversized Hollow Output Shaft

The output shaft has an oversized hollow bore that allows easy passage of wiring and piping, or the shaft of another device, for extended design flexibility.

Cross Rollers

Cross roller bearings are used inside the output unit for increased rigidity and minimal runout.

Motor Shaft Clamp

The motor shaft is rigidly clamped to the input shaft of the reducer for a direct transfer of power from the motor. The motor base is designed to absorb error in alignment during assembly. (Patent pending)

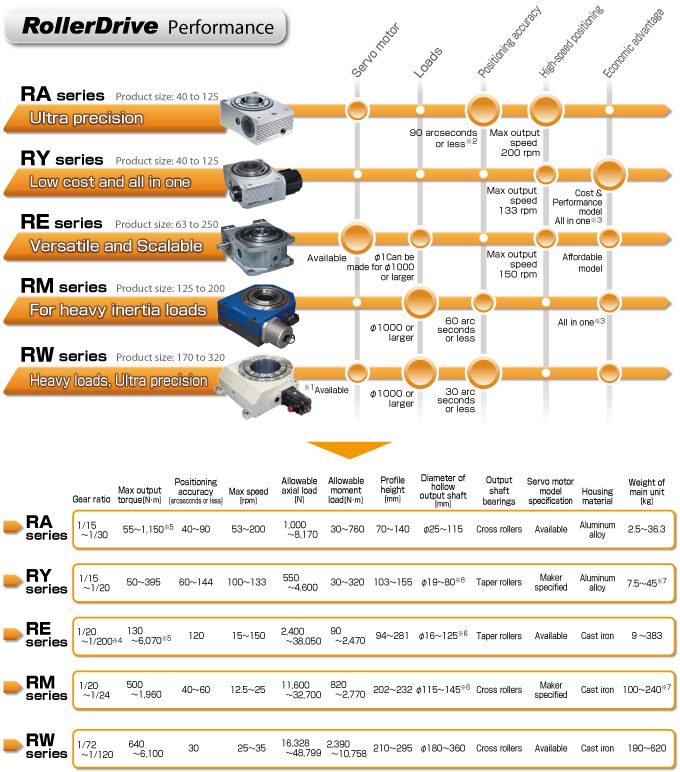

*1 Some combinations may not be practical for certain operating conditions. *2 Circles at each intersection denote overall accuracy. The larger the more accurate. *3 "All-in-one" refers to packages that include a servomotor and amplifier. *4 Ratios from 1/100 to 1/200 require optional attachment. *5 Maximum output refers to maximum torque at starts and stops. *6 The hollow shaft is fixed. On the RM series, the RM200 features a fixed center shaft. *7 Weights are listed with the servomotor mounted.