Sankyo Seisakusho Co. has gathered together the best in motion control technologies, including positioning, materials feeding, and machine tool operations. We have also accumulated lots of intellectual tools to support them, such as software and analytic techniques. Sankyo products that have these technologies embedded in them are integrated into many production systems and production lines, in such industries as automobile manufacture, aerospace, medicine, food production, and machine tool manufacture.

Patents

Thanks to the large accumulation of know-how that has grown out of our history of research and development, Sankyo Seisakusho has been granted many patents.

Our patents have allowed us to establish a competitive advantage in our markets, which we are able to maintain because we continue to provide valuable products that no other companies can field.

■Here are some things we've developed

-

The shrink tunnel

1970

A heat source is integrated into a conveyor system, and it heats an object covered by shrink-plastic film, so the film fits closely to the object, adapting to its shape.

-

Sandex D series (with shaft drive)

1973

A rotary positioning device for factory automation (FA) using a roller gear cam.

This rotary positioning device transmits drive power by engaging a screw-shaped roller gear cam and multiple roller followers arranged radially around an output shaft.

Our unique pre-pressurizing mechanism eliminates backlash. This rolling transmission mechanism provides high transmission efficiency and its precision is not degraded by wear.

-

Torque limiter -- TS series

1975

This is an overload protection device. When great torque, exceeding a machine's design value, is applied to a machine for any reason, this device stops operating and eliminates this excessive torque to protect expensive machinery and prevent human injury.

-

Ampoule inspection machine

1980

This inspection system is used to detect undissolved foreign materials in ampoule solutions, and its optional appearance-inspection function can be used to detect abnormalities in the appearance of the ampoules.

-

Variax V60A series

1983

A press materials feeder using a roller gear cam.

This feeder pushes material while grasping it using a fan-shaped roller for powerful, high speed feeding.

-

D series circular table (Camtron)

1987

A compact circular table with a drive motor directly connected to the input axis of a roller drive.

Smooth rotational positioning with no backlash. Its clamp-free processing greatly reduces downtime.

-

RA series RollerDrive

2005

We designed a system to mechanically reduce the speed of rotation of a servo motor, and thereby obtain strong torque, good rigidity, and reliable stability. This includes a unique pre-pressure mechanism for zero backlash, so this system can deliver the exact output motion dictated by the input control command.

This high performance rotary positioning device delivers great efficiency and less wear during operation due to its use of rolling transfer. Its thin and compact design is thanks to the orthogonal layout of input and output axes and the large diameter shaft hole.

-

Can manufacturing line

2006

This system grips sheet material at both ends and takes it from a destacker to a sheet feeder and then on to a press.

This rapid and highly precise materials feeding system allows continuous manufacturing, with no need to dummy-punch the seams.

The grippers can be optimally adjusted to the correct position to adapt to the metal die used. This is a cam-operated hydraulic system.

-

Glass transport robots.

2008

When a RollerDrive is used in a robotic joint, the robot can be moved with precision.

RollerDrives includes a unique pre-pressure mechanism for zero backlash. So, when they are used for robotic joints they can deliver exactly the output motion called for by the control command.

-

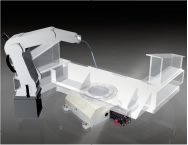

Welding positioner

2013

This turntable positioner is used to feed various workpieces, including automobile parts, to a welder.

Because it incorporates one of our RW series devices, the system can provide rotary positioning at approximately twice the speed of ordinary positioners.

Using this positioner, you can construct a system using the minimum number of robots.

Various jigs are available as options for each application.

-

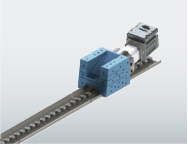

LinerUnit -- CS series

2013

LinerUnit is a speedy and powerful linear drive device using a roller gear cam mechanism.

It easily enables long feed strokes by the simple addition of rails in a way that would be difficult using other equipment.

The drive rail and servo motor are arranged in parallel, which saves space.

It can be used to feed robots, gantry loaders, and transfer machines.

-

Large tilt table

2015

A large and powerful tilting circular table (a rotating table with a diameter of 1000mm) is driven by two tilting axes.

■Patented technology

| Rotating planetary roller transfer unit | (Patent No.1372216) |

|---|---|

| Plate material feeder | (Patent No.2055407) |

| Tool exchanger using a cam device | (Patent No.4991625) |

| Cutting process unit and machine tool | (Patent No.4446003) |

| Clamping device and rotary table device | (Patent No.7793567) |

| Cam device | (Patent No.4898377) |

| Motor coupling mechanism and cam device | (Patent No.7649287) |

| Cam device and tool exchanger | (Patent No.4848239) |

| Motor coupling mechanism and cam device | (Patent No.4898174) |

| Power transmission device and integrated plate-feeder | (Patent No.7229380) |

| Oil seals and equipment with incorporated oil seals | (Patent No.4695868) |

| Table device for machining | (Patent No.4644476) |

| Tilting rotary table device | (Patent No.4538292) |

| Detachable motor | (Patent No.4411140) |

| Machine tools | (Patent No.4423099) |

| Motion conversion equipment and incorporated materials feeder | (Patent No.4628738) |

| Detachable motor | (Patent No.4411140) |

| Gripper feed | (Patent No.4384537) |

| Cam gripper feed (Grip parameters) | (Patent No.4494857) |

| Device for adjusting the timing of release of cam feeders | (Patent No.4494867) |

| Pick & place equipment using cam devices | (Patent No.4512236) |

| Rocking cam housing device and a workpiece shifter that uses it | (Patent No.4634577) |

| Cam device | (Patent No.4634575) |

| Cam follower mounting structure | (Patent No.4384751) |

| Cam follower securing structure | (Patent No.4603643) |

| Mechanical press equipment | (Patent No.4233683) |

| Torque compensator | (Patent No.4084477) |

| Fluid pressure circuit compensator and a cam device with this compensator | (Patent No.5943860) |

| Variable torque offset device | (Patent No.3799123) |

| 2-dimension movement generator | (Patent No.3884803) |

| Safety equipment: prevents covers (top and bottom, opening and closing) from unintended movements | (Patent No.3752305) |

| Variable torque flattening equipment | (Patent No.3907742) |

| Intermittent indexing device equipped with a mechanical hand | (Patent No.3471452) |

| Support equipment for a coiled materials feeder | (Patent No.5413304) |

… and lots more. We have obtained 580 patents, as of January 2017.