In terms of performance, Sankyo's roller gear does for rotary motions what the ball screw does for linear motions. The roller gear cam mechanism consists of a roller gear and globoidal cam. Similar to the preloading structure of a ball screw, the roller gear has no backlash, and transfers power by rolling contact for strong rigidity and excellent efficiency. And no clamping is necessary.

RS Series (4 models)

| RS100 | RS170 | RS200 | RS240 |

Permanent accuracy

By adopting our roller drive mechanism, there is no deterioration in the internal parts of the RCD Circular Table and its accuracy does not deteriorate after long-term use. It has excellent durability.

No routine calibration or adjustment work is required.

No routine calibration or adjustment work is required.

Excellent performance characteristics due to the zero-backlash design

With our roller drive mechanism, it is possible for repeated output operations to be equally precise, without being disturbed by external forces. Because it achieves high-precision positioning with a rotational accuracy of 10 seconds or better, it can also be used for heavy cutting on hard steel.

No clamp operation

Since the roller drive CNC has zero play due to its design, it does not require any clamping operations.

With this design, clamping and unclamping time is effectively eliminated and no other energy source is need, unlike conventional hydraulic systems.

With this design, clamping and unclamping time is effectively eliminated and no other energy source is need, unlike conventional hydraulic systems.

No Maintenance and Excellent Price Performance

Since the torque is transmitted by rolling contact, the internal mechanism does not wear and the positioning table always maintains its initial level of accuracy, even after long-term use.

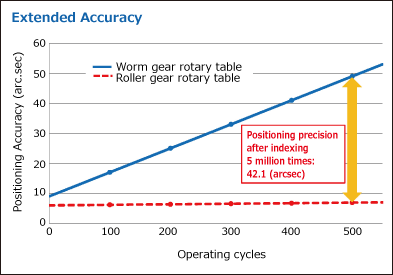

<Operating conditions>

Table size: Output table diameter; 170mm

Load inertia: 0.5kg・m2

Indexing angle: 36 ° (1 direction indexing)

Indexing time: 0.35sec

*The roller drive results in the graph on the left are the measured values from our dynamic operating test.

(Both cases used testing machines with the same table diameter)

<Operating conditions>

Table size: Output table diameter; 170mm

Load inertia: 0.5kg・m2

Indexing angle: 36 ° (1 direction indexing)

Indexing time: 0.35sec

<Accuracy after 5 million indexing operations>

| Item | Worm gear | RollerDrive |

| Variation in accuracy | 42.1sec (assuming there is no maintenance) |

0.9sec |

| Backlash | 18μm | 0 |

(Both cases used testing machines with the same table diameter)

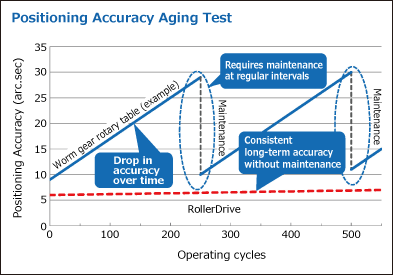

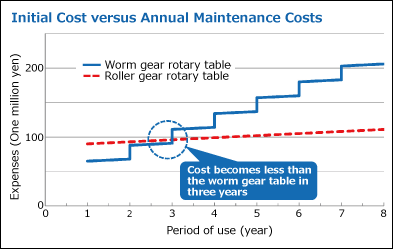

With the roller drive CNC, the variation of accuracy due to aging is extremely small, so routine maintenance costs are significantly reduced.

The graph is based on the following conditions:

・Worm gear circular tables require maintenance work twice a year.

・Both cases assume the annu al maintenance costs

(oil changes, and such.) are 3%.

*Both cases are for the same diameter table.

The graph is based on the following conditions:

・Worm gear circular tables require maintenance work twice a year.

・Both cases assume the annu al maintenance costs

(oil changes, and such.) are 3%.

*Both cases are for the same diameter table.

Cutting tool grinding

Higher accuracy by Zero-backlash movement

Processing auto parts

High-speed positioning reduces the time spent on non-cutting operations

Processing auto parts

High-speed positioning reduces the time spent on non-cutting operations

Processing auto parts

5-axis precision, simultaneous, continuous processing

Medical parts

Compact 5 axis

Molding parts

High speed & accurate continuous cutting

RS Specifications

| Description | Unit | RS100 | RS170 | RS200 | RS240 |

| Table OD | mm | φ100 | φ170 | φ200 | φ240 |

| Table Bore Diameter | mm | φ50 H7 | φ80 H7 | φ100 H7 | φ130 H7 |

| Center Height | mm | 125 | 115 | 125 | 132 |

| Gear Ratio | 1/60 | 1/60 | 1/60 | 1/90 | |

| Max Table Speed | rpm | 75 | 75 | 75 | 55 |

| Positioning Accuracy | arcsec | ±15 | ±15 | ±10 | ±10 |

| Repeatability | arcsec | 8 | 8 | 4 | 4 |

| Product Weight | kg | 38 | 44 | 56 | 72 |

>> RCD Series

Standard model

Motor side surface

mounting type

Motor side surface

mounting type

>> RCD Series

Standard model

Motor rear surface

mounting type

Motor rear surface

mounting type