Design technology

Improving design quality: assuring the level of product safety and increasing customer confidence

In order to improve the precision and safety of our products, our development and design divisions perform repeated design reviews (DRs) in collaboration with experts from each department (the production technology, manufacturing and quality assurance departments). Teams identify any substantial problems in each process, try to eliminate nonconformities, and focus on attaining the production targets of safety, security, and high quality.

Repeated design reviews (DR exams 1 & 2)

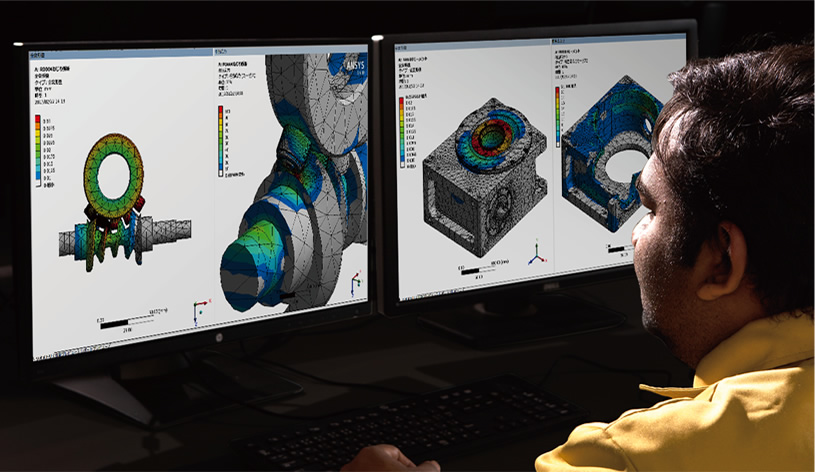

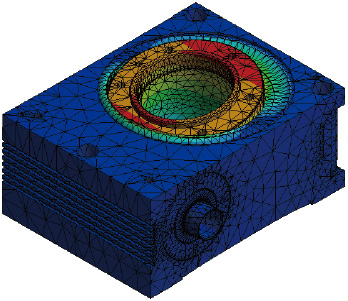

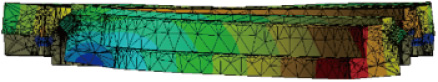

Structural analysis and simulation using 3D CAD: improving product

performance and making the verification period more efficient

We use FEM analysis to simulate the deformations and stresses that will occur during product use.

-

Simulating product rigidity

-

Simulating bearing rigidity

-

Evaluating product validity:

product evaluation and endurance

testingNew product development includes checking for conformity with the required specifications, performing thorough endurance tests, and inspecting for any faults, before committing to actual mass production.

Throughout this process, the products used when running the endurance tests are disassembled for examination. Many specific aspects of the parts are checked for problems.

Based on data about the faults found during these thorough checks and the performance of prescribed countermeasures, we work to reach the highest product quality and optimization of product functions. -

Durability tests: imposing challenging loads on our products

| Focus on qualit | Quality assurance | Design technology | Production facilities | Thermal treatment | Personnel training and education |